THE BEST HARD HATS OF 2025 | TESTED BY ACTUAL PEOPLE IN THE TRADES

DAX FIFTY50 CARBON FIBER TYPE I HARDHAT

KEVY SAFETY TYPE II HARD HAT

MSA 10145798 SKULLGARD TYPE I HARD HAT

KLEIN TOOLS 60407 VENTED TYPE I HARD HAT WITH LIGHT

HONEYWELL MATTERHORN A89 TYPE II HARD HAT

BULLARD VTKBR VECTOR TYPE II HARD HAT

BOTTOM LINE

The DAX Fifty 50 provides good protection. And it’s one of the coolest looking hard hats around, coming in a range of colors. But it’s expensive, and some reviewers have issues with the durability of the paint and suspension.

The Kevy Safety Type II - Class C hard hat is a lightweight safety helmet that exceeds ANSI Z89.1 standards, blending a classic look with modern features like modular mounting and superior comfort, setting it apart from the rest.

The Skullgard has a retro yet modern look, decent weight, and electrical protection of up to 2,200 volts. It has no extra features and some users complain about the quality of the finish. Nevertheless, this is a solid, attractive hard hat.

The 60407 has adjustable vents that allow more air circulation, and it comes with an attachable light. It also has slots to mount other accessories. This is the heaviest helmet here, but the extra features and low price make it a good option.

The Matterhorn is a Type 2 hard hat that protects against side impacts as well as vertical hits. And it’s rated E for those at higher risk of electrical shocks. It won’t win any hard hat fashion awards, but it gets a lot done at a reasonable price and weight.

The Bullard Vector is another average-looking Type 2 that provides lateral protection along with two optional levels of electrical protection: G or E. This extra safety does not come with excess weight or a high price tag. That's a great deal of security for the money.

PROS

It undoubtedly looks cool, and the carbon fiber helps this hard hat come in at areas on able weight. There are numerous color and build options, and the synthetic leather suspension has a quality, throwback feel.

The Kevy has unmatched comfort and versatility. You're getting a classic looking safety helmet with a lot of features that meets all modern safety standards while also being made in America.

A style that makes a statement with numerous color options. Added electrical protection and tested in high temperatures. Provides adequate vertical impact protection from a trusted industry brand.

It comes with a snap-in light and mounts for more accessories, such as hearing protection or a face shield. Made in the US and available in many colors and builds. The vents allow in more air to cool the wearer's head.

Extra Type II side protection and an “E” high-voltage rating (up to 20,000 volts)while still weighing just less than a pound. Includes side slots to mount accessories, and a trusted company manufactures it.

Again, this helmet offers additional horizontal protection and either E or G electrical ratings. It comes in 8 different colors, including two “high-visibility” options: orange and yellow.

CONS

While some reviewers swear the DAX Fifty50 is comfortable, others don’t. Some note that the paint chips and fades easily, and the suspension may wear out or break. Finally, there are no attachment points for accessories.

Expensive - The Kevy Safety hard hat is a compression molded safety helmet made in Sweetwater, Texas by American blue collar professionals, and you pay for the quality.

What you see is what you get: there are no extra features. The build feels a little flimsy, and the suspension is difficult to install. Finally, some reviewers report that the paint coating does not hold up well to high temperatures.

The 60407 weighs in heavy at 1.3 lbs. (590 grams), though that involves the light. Some reviewers note that the light is not easy to use and isn’t high quality, so aftermarket accessories might make more sense.

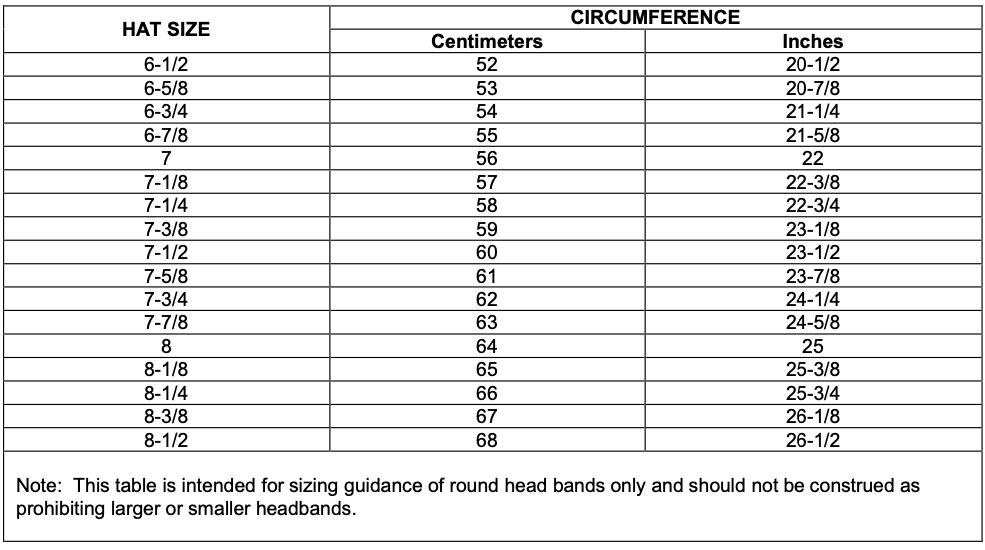

Plain-looking, front-brim only, and not a ton of build options. This hard hat is no tone-size-fits-all—it’s advertised to fit head sizes from 6.5 to 8.

While the helmet can provide either G or E electrical protection, many sellers don’t specify which—so, order carefully. Front brim only, so there’s less shielding surface area on the back and sides.

TESTING DATA

Meets ANSI Z89.1- 2014 requirements for Type I (vertical impact), Class C (conductive; does not protect against electricity).

Meets and Exceeds ANSI Z89.1- 2014 requirements for Type II,Class C with chin-strap.

Meets ANSI Z89.1- 2014 requirements for Type I (vertical) impact and Class G (general—limited electrical protection).

MeetsANSI Z89.1- 2014 requirements for Type I (vertical) impact and Class C (conductive).

Meets ANSI Z89.1- 2009 requirements for Type II (vertical and horizontal) impact and Class E (electrical).

Meets ANSI Z89.1- 2014 requirements for Type II (vertical and horizontal) impact and Class E (electrical) or G (general).

Your Guide to the Best Hard Hats and Construction Helmets

There are plenty of hard hats to choose from, but which ones provide the best combination of protection, value, style, and comfort?

You’ve got to choose a construction helmet that meets the right safety standards for a job site and is built to last.

Is a $30 hard hat enough for the job, or does headgear pushing $300 really provide extra features or safety that make it worth the price?

What about all the other factors, such as size, weight, airflow, accessories, and testing that go intodefining the best hard hat and construction helmet?

How We Decided

Each hard hat featured on this page and several that aren’t was assessed based on manufacturer specifications, testing data, and consumer reviews.

12

Testing data according to US, Canadian, and European standards

12

Manufacturer Specs

62

Consumer Reviews

Hard Head Veterans takes evaluating all types of helmets very seriously, given that safety and performance are on the line. We’re committed to providing the information you need to make the right choice, so we strive to be unbiased in our reviews and present a range of good options.

The fact is that all of the hard hats on this page do the essential job—protect your head—according to the specific safety standards that each model meets. So, picking the right one first depends on which safety and testing standards your job site calls for, followed by evaluating comfort, durability, style, price, and other factors.

To understand the safety requirements, continue reading our shopping guide below!

The most important factor in choosing a hard hat is picking one tested according to the correct safety standard and rated to provide specific protection. In the US, construction helmets must meet benchmarks from the American National Standard for Industrial Head Protection (ANSI Z89.1), either the 2009 or 2014 edition. Other standards govern hard hat safety in Canada (CSA Z94.1-15) and Europe (EN 397:2012+A1:2012, etc.), but this guide focuses on the ANSI standard used in the US.

Wherever you work, make sure a hard hat meets the standard that applies to your country and work environment. Legitimate manufacturers and sellers will specify the impact type, electrical class, and other vital features, and each helmet should have a permanent label inside the shell that lists this information.

TYPE I

Type I hard hats meet ANSI Z89.1 testing for protecting the top of the head from impacts and penetrations. This means tools, debris, and other items falling from a reasonable height—or whacking your head on a low-hanging object.

TYPE II

Type I hard hats meet ANSI Z89.1 testing for protecting the top of the head from impacts and penetrations. This means tools, debris, and other items falling from a reasonable height—or whacking your head on a low-hanging object.

PRODUCT IN DEPTH

MSA 10145798 Skullgard Type I Hard Hat

Design Difference

The MSA Skullgard is specifically designed to weather extreme temperatures. These hard hats have been “tested to radiant heat loads producing temperatures up to, but not exceeding, 350-degrees Fahrenheit.” It's made in the USA from US materials. The MSA Skullgard is the helmet of choice for most Ironworkers, it has stood the test of time and is a solid entry level hard hat.

HARD HAT CLASSES: PROTECTION AGAINST ELECTRICITY

CLASS C (CONDUCTIVE)

Conductive means that the hard hat conducts electricity and does not provide electrical protection. Most hard hats fall into this category and are used on job sites where the risk of electrocution is low.

CLASS G (GENERAL)

Class G hard hats are “all-purpose” models that provide some electrical protection—they’re tested up to 2,200 volts. They can be a safer option that’s also suited for general construction work.

CLASS E (ELECTRICAL)

These models are the real deal when it comes to electrical safety, and they’re typically used by specialists who regularly work around high-voltage sources. Hard hats are tested to resist up to 20,000 volts.

Did You Know?

Hard hats should be regularly inspected for signs of cracks, dents, or too much stiffness — ideally every day. You should also check the suspension system for rips, frays, and a loss of elasticity. And if a helmet takes a hit, it should be replaced.

Most hard hat shells can last about 5 years and suspensions 12 months—if cared for right!

For Your Safety

It can be tempting to flip a hard hat around when you need to see something better or get close to it, but hard hats are tested to be worn in specific ways.

Only reverse-wear hard hats that meet ANSI standards can be rotated and still protect you properly. Look for the reverse-wear logo on the inside of a hard hat to see if it’s rated to do it!

HARD HAT SAFETY TESTING

Test Types

Legitimate hard hat manufacturers send samples of their helmets to independent testing labs to ensure they measure up toANSI Z89.1 and provide enough protection. If a seller advertises a hard hat as “Type I” according to “ANSI Z89.1-2014," that indicates it's passed the tests for top-of-the-head protection in the 2014 edition of that standard. But if you want to be sure, any reputable company will provide detailed testing reports on request!

Here are a few of the tests conducted on different types and classes of hard hats:

All hard hat types are tested for flammability. Testers apply a Bunsen burner to the shell for five seconds, and the hard hat passes if no visible signs of flame remain.

Force transmission: both hard hat types are placed on a headform (dummy head) and hit with an 8 lbs. impactor (an anvil or steel ball) at a velocity of 18 ft/s. Construction helmets must not transmit a force to the headform that exceeds 4,450 N (1,000 lbf).

Apex penetration: Testers drop a pointed 2.32 lbs. steel penetrator on top of a helmet at a velocity of about 23 ft/s (7 m/s). The helmet passes the test if the penetrator does not cut through the helmet to touch the dummy head.

Electrical insulation: Testers hit Class G hard hats with 2,200 volts for one minute, while Class E models are exposed to 20,000 volts for three minutes. Hard hats pass if no leakage of 3 milliamperes (G) or 9 milliamperes (E) is detected.

Type II hard hats undergo these additional tests to make sure they can take horizontal hits:

Impact energy attenuation: The lateral (side) protection is tested by dropping the side of a helmeted dummy head on an anvil at about 11.5 f/s (3.5 m/s). The maximum energy transmitted to the head can’t exceed 150 times the acceleration of gravity.

Off-center penetration: The same pointed steel penetrator from the apex penetration test is dropped from a height that creates an impact velocity of about 16.4 f/s (5 m/s) on the front, side, and rear of the helmet. To pass the test, the penetrator can’t touch the dummy head.

There are additional ANSI tests for optional features, including chin-strap retention ,high (HT) or low temperatures (LT), high visibility (HV), and reverse-wearing (the ability to wear a hard hat backward without compromising protection). If a manufacturer tests for these additional features and passes, the product page and the inside label should tell you!

Check out this video of impact and penetration testing:

PRODUCT IN DEPTH

Bullard VTKBR Vector Type II Hard Hat

Features

The Bullard VTKBR Vector achieves its Type II protection with a two-part shell design. The outer shell is made of polyethylene, a lightweight thermoplastic, whereas the shell's interior is filled with polystyrene foam that absorbs and distributes the energy of an impact.

PRODUCT IN DEPTH

Kevy™ Hard Hat

Suspension Systems

The Kevy features a quick attach/detach magnetic Fidlock Suspension System with a rear tightening ratchet. It works on or under the chin, allowing for easy adjustment and single handed, gloved operations.

HARD HAT FEATURES TO CONSIDER

Weight

When it comes to comfort on long workdays, weight is a big factor. Hard hats tend to be lighter than some protective helmets (like ballistic and motorcycle helmets) while equal or slightly heavier than others (bicycle helmets). Most of them weigh about a pound.

As far as protection goes, Type II helmets are sometimes a little heavier because of their bigger protection area. But if two given helmets of about the same weight are listed as Type I or Type II (or E or G), each should meet the protection standard specified.

Thus, weight is a matter of personal preference—and lighter is usually better. Accessories will, of course, add weight. For example, the heaviest model on our list comes with a detachable light and its mount. So, you’ll need to decide whether accessories like lights, sun shades, or cooling elements—if a helmet has attachments for them—are worth the trade-off in extra ounces.

ADDITIONAL HARD HAT FEATURES TO CONSIDER

Accessories

Many hard hats come with accessories, but each model varies based on whether it has slats, mounts, or other ways to connect some of them. So, you’ll want to decide what you might need to add before you purchase a helmet.

Some potential accessories include:

Sweat-wicking bands, do-rags, or brow pads that manufacturers design to fit under hard hats.

Attachable sun shades — 360-degree or just the back of the neck.

Earmuffs can either be cap-mounted and model-specific or aftermarket.

Headlamps are either designed to attach to a specific helmet or aftermarket models that wrap around the top via straps.

Option chin straps for high-windand rough environments.

PRODUCT IN DEPTH

Klein Tools 60407 Vented Type I Hard Hat With Light

Airflow

This hard hat features adjustable vents that can be open or closed by degrees to let more air circulate. The suspension has an "open" design that works with this feature to maximize airflow. The60407 includes a one-year manufacturer’s warranty.

HARD HAT FEATURES TO CONSIDER

Retention System

The retention system—aka the network of straps on the inside of the hard hat—is crucial for ensuring fit, comfort, and that your headgear provides good impact and penetration protection.

Hard hats typically come with a four- or six-point retention system and a “ratchet suspension,” which is basically a little round knob at the back that you twist to tighten or loosen the straps. Some models ditch the ratchet for "quick fit" sizing, and others feature a chin strap that keeps a helmet on your head in heavy winds or other extreme conditions.

If you like the look of a helmet but don’t like the retention system, it’s not a good idea to swap it out for another one that’s not designed for the hard hat. Shells and suspensions work together and are tested together, so mixing and matching them could compromise safety. If you don’t like the suspension, it’s best to find another hard hat or a different, compatible suspension from the same manufacturer!

HARD HAT FEATURES TO CONSIDER

Comfort, Sizing, And Liner

You’ll want to make sure a hard hat has a snug fit and avoid wearing anything underneath it (like a baseball cap) that disrupts the retention system and shell. Remember, hard hats are designed and tested to prevent severe impacts and injuries based on how those two parts interact.

Most hard hats come with "sweat-wicking" liners that may help keep sweat out of your eyes, while other manufacturers sell brow pads or headbands that work with the helmet.

Some hard hat models say they fit “any size.” Others provide a specific size range. So, if necessary, make sure to measure your head to see if the latter models fit. Remember, a hard hat should fit snug enough to stay on your head without slipping, pinching, or irritating your skin.

PRODUCT IN DEPTH

DAX FIFTY50 Carbon Fiber Type I Hardhat

Design Difference

Whereas most helmets on this list are exclusively made of thermoplastics, this hard hat features a carbon fiber-reinforced resin shell in a layered build. This is not 100% Carbon Fiber, but fiberglass with a Carbon Fiber layer. Carbon fiber is a very rigid yet lightweight material. It does have two main downsides and that is it's brittle and does conduct electricity. So you won't find this helmet in a Class E option. It will also chip easily if not taken care of.

HOW MUCH SHOULD I PAY FOR A HARD HAT?

Honestly, pricing is all over the place on hard hats, though they are a lot cheaper than some other types of safety helmets. The models featured on this page range from a little over $25 to almost $400! The bottom line is that you get what you pay for. Many hard hats are made to only last so long. They are made with cheap materials and cheaper methods. They may or may not meet standards for your 19.99 Amazon specials and they won't last long either. If you make your living under a hard hat, and wear one daily, invest the money for a high end piece of gear that will keep you comfortable all day.

Comparing "price" vs. "value" starts with looking at the helmet's type and electrical class and making sure those meet your needs. For example, an ANSI Type I hard hat required by OSHA rules in the US won’t necessarily cut it if you work in Canada—you’d need something also rated according to the Canadian Standards Association (CSA Z94.1-15).

As long as your head is sufficiently protected, you’re good. However make sure to confirm that your hard hat meets your job site requirements. From there, it’s all about the combination of features, fit, weight, and look that you’re willing to pay for. One last thing to remember is what does the warranty look like? Some hard hats are cheaply made, and while they might meet standards out of the box, they will quickly fail after a year or two of use.

TIPS AND TRICKS

Hard hats are a straightforward piece of equipment, and it’s pretty easy to maintain them.

Clean them regularly according to the manufacturer's instructions—warm soapywater is fine—and avoid storing them in sunlight or high heat, as UV and extreme temperatures can reduce their useful life. Don't apply any stickers, glue, or paint that is not explicitly approved for use on a hard hat—some chemicals can compromise the shell. Never engrave a helmet or drill any holes in it!

Inspect the helmet before putting it on your head, looking for cracks or stiffness in the shell and frays or tears in the liner. You can do the “squeeze test:” put both hands on either side of the shell and squeeze inward about one inch. If it bounces back quickly with no deformation, it’s in good shape. You can also do the test on a brand-new helmet to compare the result.

Replace a hard hat if you see any signs of physical damage or the shell takes an impact. This is an ANSI rule—a helmet may look fine, but hairline fractures or other damage could weaken the protection.

With good care and no impacts, a hard hat lasts years. The general rule is that a suspension should be replaced at least every 12 months and the shell within 5 years—though shells subject to heavy use should be replaced in as little as 2 years.

Manufacturers will often print dates on the inside of the shell, but regularly inspecting a hard hatis crucial for knowing when to get a new one. For a thorough guide to hard hat inspection and maintenance, read this!

PRODUCT IN DEPTH

Honeywell Matterhorn A89 Type II E Hard Hat

Suspension Options

Honeywell makes everything under the sun, and does a solid job at it. This is a no frills hard hat that will get the job done. The Matterhorn has two suspension options: a 4-pt. nylon ratchet or “quick fit” suspension, with the ratchet being more adjustable to different head sizes. Both suspensions include three levels of height adjustment.