The discovery of UHMWPE

Scientists at the Dutch multinational corporation DSM discovered ultra-high molecular weight polyethylene fibers by accident in 1963, during a series of experiments in fractionating out different polyethylene lengths from a solution. These experiments were probably done with an eye towards the production of packaging materials.

The researchers quickly discovered that these very long-chained polyethylene fibers were incredibly strong. But initially, only small amounts of the fibers were produced, and they seemed to be more of a scientific curiosity than a useful material. Those early UHMWPE fibers were nearly impossible to orient in solution, so they’d typically form intractable aggregates and clumps. As discussed in part one of this series, fiber composites benefit from a linear orientation, and a tangled and knotted clumps of them have very little strength or practical use.

But in 1978, 15 years after the original discovery, DSM engineers discovered the now-famous gel-spinning method. Dr. Piet Lemstra, a chemist who worked on the project, described this crucial innovation:

It’s actually very simple. The more you dissolve the long chain molecules in a solvent, the more they become separated. Then you cool it down to a gel state and the molecules are more or less disentangled, so it is easy to stretch them. You can then remove the solvent, or later, during the stretching/drawing process – either way you end up with nearly perfectly aligned molecules.

A diagram illustrating the "Process for producing high tenacity, high modulus crystalline thermoplastic article and novel product fibers," aka the “gel-spinning” method. Source: European Patent Office

The development of this gel-spinning process enabled the industrial production of UHMWPE fibers. But DSM was not an industrial fiber company; it was—and, to a large extent, remains after a merger—a “health, nutrition and materials” product company that discovered UHMWPE fibers by accident.

The UHMWPE team at DSM was a self-described skunkworks crew that did experiments in their spare time and on weekends. The MBA corporate types at headquarters had little interest in figuring out how to develop UHMWPE fiber products, and outside consultants brought in to evaluate its commercial potential did not think very highly of it.

“This company said the fiber was just candlewax unable to resist high temperatures and it

lacked any good properties. They saw no future in it,” commented Lemstra. “And the management at DSM believed them.”

So, the company eventually put UHMWPE development on hold.

A new corporate competitor becomes a key licensee

Just a couple of years later, in the early 1980s, the “American aerospace, automotive and engineering company” AlliedSignal (now Honeywell) obtained a patent on a strikingly similar UHMWPE fiber product.

It seemed identical to DSM’s fiber in all respects save one: AlliedSignal claimed that the melting point of their material was 20–30 degrees higher. But as it turned out, the two UHMWPE fibers were effectively the same; the difference was due to a methodological error. Since DSM’s patent had priority, AlliedSignal had to purchase a license for it, which had major consequences for both companies.

This licensing arrangement finally convinced DSM’s management of the commercial potential of UHMWPE. Now intrigued but still convinced the company couldn’t produce it in-house because they weren’t a fiber company and had no expertise in mass producing such materials, DSM reached out to Toyobo in Japan.

Toyobo was and remains the world’s largest producer of carbon fibers, and its personnel seemed impressed with UHMWPE’s potential. The two companies worked out a production and distribution arrangement where Toyobo would make fibers under license for DSM, culminating in the joint commercialization of Dyneema® fiber. Initially, the companies didn’t target the military market; the material was primarily utilized in lightweight ropes, nets, and sports equipment.

AlliedSignal, with its license in hand and no potential intellectual property disputes on the horizon, started marketing its own fiber, Spectra Shield®, as a ballistic competitor to Dupont’s Kevlar®. The company did not meet with much success in the USA throughout the ‘80s and ‘90s. DuPont had countered their efforts with an effective marketing campaign that showed how Spectra Shield weakened at moderately high temperatures—starting at roughly 160°F.

So, the US military, characteristically wary of new materials and armor systems, came down on DuPont’s side and viewed Spectra Shield with guarded suspicion.

The CGF Gallet Spectra Helmet in OD Green. Image source: Martial Grenot via Wikipedia (CC BY-SA 2.0 fr)

The first UHMWPE Armor and the Spectra Helmet

The US military was slow to adopt UHMWPE but generously funded some research into the material. In 1987, AlliedSignal initiated a military-funded research project (DAAK60-87-C-0089/D) for the development of a helmet similar to the military’s then-current PASGT (Personnel Armor System for Ground Troops) headgear but made out of Spectra Shield composites. It was perhaps the first project to investigate UHMWPE in rigid armor systems, and much of the effort consisted of identifying the optimal resin system for use with UHMWPE fiber laminates.

Researchers assessed multiple resin systems over five years through the development and testing of many prototype batches. They eventually settled on a 50:50 mixture of a vinyl ester resin with polyurethane—very similar to the resins used in helmets and hard armor laminates today. With this resin, the project’s “Spectra 1989” helmet performed roughly as well as the Kevlar PASGT, both in terms of backface deformation and absolute ballistic performance, but at a 20% lighter weight.

Despite this promise, for reasons that are not entirely clear, it would be nearly 25 years before UHMWPE composite helmets were issued to American troops. Other militaries, however, were more open-minded. (Or perhaps less beholden to DuPont, which, back then, was completely opposed to the adoption of UHMWPE fiber composites in armor.)

AlliedSignal exhibited its Spectra-Shield material at the French defense trade show Milipol in 1991. The timing was right; it was just as low-level conflicts in the Balkans were starting to heat up and European militaries were looking to modernize their infantry forces, which were still often issued WWII-era helmets.

AlliedSignal immediately got Spectra Shield in front of SCERCAT, the French Army’s primary research lab, which commissioned some rapid, impromptu studies into the suitability of the material in comparison with other composite, polymer, and metallic materials for soldier protection. SCERCAT determined that Spectra Shield performs roughly 80% better than the manganese steel then used in helmets, and they also noted it was superior to Kevlar. This was a monumental first.

By 1992, AlliedSignal was shipping PASGT-style Spectra helmet prototypes to the French military for serious testing and evaluation. By June of the following year, authorities worked out a manufacturing agreement with the French manufacturer CGF Gallet, and the French Army adopted the “CGF Gallet Spectra Combat Helmet”—often shortened to “Spectra helmet.”

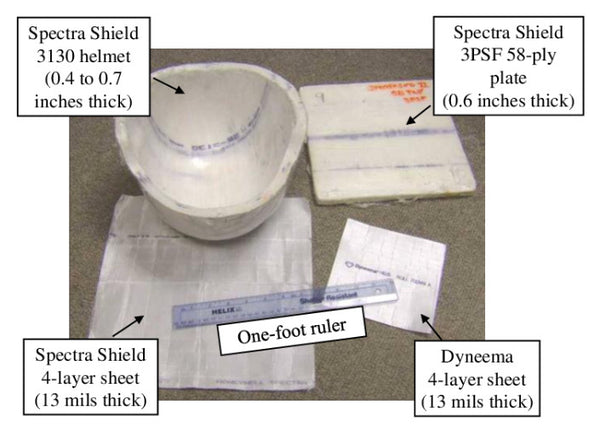

Image source: Chiou, C., et al. "Nondestructive characterization of UHMWPE armor materials" via Semantic Scholar

The CGF Gallet Spectra Helmet offered extremely good performance compared to the other helmets of that era:

- The largest Spectra helmets weighed about three pounds.

- When new, they exhibited a V50—the point where half of projectiles don’t penetrate—against the FSP (a NATO Fragment Simulating Projectile (FSP)) of over 2,200 feet per second.

- A size large PASGT weighs north of four pounds and has a lower V50, at around 2,000 fps.

So, the aramid version of the PASGT, then in use and considered quite a “modern” helmet at the time, weighed substantially more and simultaneously offered inferior performance than the Spectra.

We could go a step further and say that the French Spectra helmet offers extremely good performance compared to today’s headgear. If you look at its ballistic resistance, weight per finished helmet, and factor in its oversized PASGT-style geometry, it is superior to the US military’s Advanced Combat Helmet (ACH) and roughly equal to 2017’s mooted “ACH Gen II.” The Spectra helmet is also roughly on par with some of today’s UHMWPE helmets, such as Galvion’s P series.

That’s not bad for something that was almost fully developed in 1989 and issued on a French Army-wide basis in 1993.

The current French Army helmet can trace its lineage back to the Spectra helmet; it is, for all practical intents and purposes, “Mark 2” of the 1993 model. But the Spectra never got the attention it deserved, and today it is mostly forgotten. It was too far ahead of its time.

The Spectra helmet’s influence on other headgear & UHMWPE armor

The Spectra helmet was not nearly as influential as it should have been, having no impact on the development of American headgear in the 1990s and 2000s. It was evaluated by Canadian forces, who subsequently developed a new helmet, the CG634. The CG634 copied the Spectra’s cut and design, but, out of an abundance of caution, it was constructed out of aramid rather than UHMWPE.

The Spectra helmet did, however, strongly influence the development of UHMWPE-based armor plates, which were largely a continuation of AlliedSignal/Honeywell’s work on rigid UHMWPE fiber composite systems. (DSM first discovered and pioneered UHMWPE fibers, but it must be noted that AlliedSignal/Honeywell pioneered UHMWPE composites and composite armor with their work in the late 1980s.)

Shortly after the class-leading performance of the Spectra helmet became apparent, rigid panels of similar construction were tested for use (a) behind ceramic tiles in ceramic armor plates, and (b) in thick standalone body armor plates.

The UHMWPE panels behind ceramic plates exhibited starkly superior performance in comparison with the fiberglass and aramid backers that were standard at the time. They rapidly—within just a few years—began to replace both materials in all but the lowest-end ceramic armor systems.

The latter standalone UHMWPE plates were quickly noted for their excellent performance against lead-core ball rounds such as the 7.62x51mm M80, but they did not exhibit a performance advantage over ceramic armor systems against threats with steel cores or very high impact velocities. Because steel-cored threats were (and remain) extremely common, these early UHMWPE composite plates were not seriously considered for mass adoption by any military but have seen service in niche roles.

It should also be noted that the performance of UHMWPE composite armor plates without a hard strike face has improved in the nearly 30 years since the original plates were tested. Today, in some cases, a 10x12” UHMWPE composite armor plate that weighs 2.5 pounds can stop the hard-hitting mild steel core 7.62x54mmR LPS—far beyond the capabilities of UHMWPE composite armor plates made in the 1990s and 2000s.

So, while US military helmets may not have been directly influenced by the Spectra helmet, ultra-high molecular weight polyethylene armor plate development was. And advances in UHMWPE-based armor plates eventually led to the development of the Enhanced Combat Helmet (ECH), which, in turn, has had a huge impact on subsequent US military gear.

Thus, the evolutionary chart of the modern helmet, from a materials perspective, goes something like this:

French Spectra helmet --> UHMWPE body armor plate --> ECH --> Integrated Head Protection System (IHPS), Ops-Core RF1, etc.

"Deidre Hooks, enhanced combat helmet team lead at Marine Corps Systems Command, fits the ECH onto Gunnery Sgt. Jose Hernandez, MCSC staff secretary administration chief." Image source: US Marine Corps photo by Jim Katzaman

The development & testing of the ECH helmet

The ECH, which derived from the UHMWPE technologies then used in body armor, was developed as a partial replacement for the ACH.

It’s something of an understatement to say that the ACH had its share of problems in Iraq and Afghanistan. The helmet lurched from scandal to scandal, some (but not all!) of which were described in the 2019 book Shattered Minds: How the Pentagon Fails Our Troops with Faulty Helmets.

One of the ECH’s problems, as perceived by Army officers in Iraq, was its lack of resistance to enemy small arms fire. Most engagements took place within 100 yards, and both sides often went for headshots. High-ranking US Army and USMC leadership demanded a light helmet that offered protection from the rifle threats seen in theater—primarily 7.62x39mm mild steel core rounds.

In 2009, the requirement was for a helmet that would be simultaneously lighter than the ACH and resistant to certain rifle threats. But when it quickly became clear that this was not possible, the requirements were relaxed to a merely “light” helmet with the ability to defeat 7.62x39mm at more or less muzzle velocity, as well as 7.62x51mm at a standoff of roughly 300 yards. And with the advances made throughout the 2000s in UHMWPE-based hard armor plates and soft armor panels, it was clear to all involved that there was only one way to achieve this: a helmet made primarily of UHMWPE.

The word “primarily” above is doing a bit of work. Unlike aramid helmets, which are usually made solely of pressed layers of woven aramid in a resin matrix, UHMWPE-based helmets are never made entirely of UHMWPE composite sheets. There are usually at least a few layers of a stiffer “structural” material like aramid or carbon fiber to ensure dimensional stability, durability, compression resistance, and reduced backface deformation upon impact.

Four vendors proposed UHMWPE-based helmets, and one of them was ultimately selected for initial experimentation and testing. By late 2010, the first prototypes were built and tested. First article testing, though, took a lot longer than that. And the helmet didn’t enter “production ready” status until 2013, four years after the program’s initiation.

By this time, opinions about ECH helmet testing in the military’s program management and development community were mixed. Here are some observations from the US Navy’s assessment:

- “Although the ECH protects against perforation by the specified small arms threat, it does not provide a significant overall improvement in operational capability over currently fielded helmets against the specified small arms threat. It is unlikely to provide meaningful protection against this small arms threat over a significant portion of the threat’s effective range. However, the ECH does provide improved penetration protection against fragments relative to currently fielded helmets. The ECH met all ballistic performance requirements.”

- “In stopping high-energy threats, the helmet absorbs the projectile energy by deforming inward toward the skull. It is unknown, definitively, whether the ECH provides protection against injury when the deforming helmet impacts the head. There is, however, reason to be concerned because the deformation induced by the impact of a non-perforating small arms threat exceeds accepted deformation standards (established for a 9 mm round) across most of the threat’s effective range.”

- “There are no definitive medical criteria or analytic methods to correlate the extent of helmet deformation to injury. However, the potential for helmet deformation to cause significant blunt force and/or penetrating trauma to the head is a concern.”

- “Structural degradation as a result of prolonged temperature and humidity exposure may be a concern for the ECH. Published data document the degradation of ballistic performance in ultra-high-molecular-weight polyethylene materials, but the long-term performance of the ECH’s specific ballistic material is unknown.”

To get to the heart of the matter:

- Evaluators had concerns about ballistic performance against rifle threats in general—for the ECH only protects against a few rifle threats and not always under “worst case” test conditions of high muzzle velocity and 0° obliquity.

- There were worries over backface deformation, which generally far exceeded the 25.4mm limits set in the ACH specification against the rifle threats the helmet was rated to stop.

- Evaluators were uneasy about the possibility of UHMWPE degradation similar to the problems with Zylon® fiber, which spurred a Zylon-product recall and a rash of lawsuits.

- There was also some consternation over the fact that the ECH would cost three times as much as the ACH to produce.

In light of these concerns, the Director, Operational Test & Evaluation Office (DOT&E) recommended that the ECH helmet not be purchased or fielded. The Army Surgeon General subsequently made the same recommendation. But warfighters in the Army and USMC communities were insistent, and they won out. The ECH was fielded; small-batch production started in 2014.

The ECH rolled out slowly but was received very favorably by soldiers and command. In fact, it was so well received that the ACH and the planned ACH Gen II unexpectedly depreciated, and the military decided to proceed with a wider roll-out of ECH-type helmets.

The new general-issue IHPS helmet was modeled after the ECH. Like the ECH, it’s made primarily of UHMWPE composites and offers protection from 7.62x39mm and similar rifle rounds.

The success of the ECH helmet creates more innovation

The ECH helmet spurred the development of lightweight UHMWPE helmets for the civilian, police, and special operations communities.

Shortly after its introduction, Ops-Core and other vendors began releasing high-end UHMWPE headgear similar to the French Army’s CGF Gallet Spectra Helmet in weight and thickness, if not shape and cut. Like the Spectra, they’re roughly 25% lighter than comparable aramid helmets such as the ACH, on an a real-density basis.

As you can see, it’s been a long and uncertain road for a material accidentally discovered by Dutch chemists six decades ago. But UHMWPE helmets have proven their worth. As both the military’s choice and the top preference of private purchasers, this strong, lightweight headgear is here to stay.

Read the next part in this series, where we discuss how manufacturers shape UHMWPE sheets and other materials into ballistic helmets.

Jake Ganor is the chemist and ballistics researcher behind Adept Armor, a developer of leading-edge body armor products and materials. If you enjoyed this article, you might also enjoy his book, Body Armor and Light Armor Materials and Systems.

Hard Head Veterans stays on top of helmet research to ensure we provide the best protection possible. Read more blog posts, and be sure to check out our gear, including a selection of the best tactical helmets and essential helmet accessories.